20 years of high-performance methanol fuel cells – innovative, sustainable, and integrated across various settings

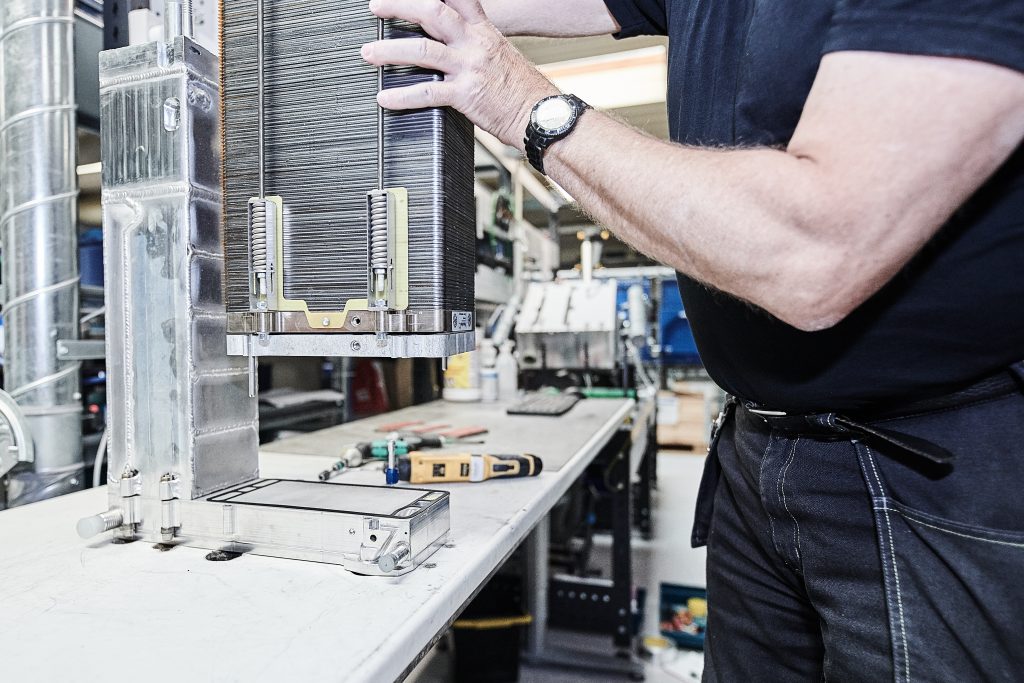

Whitecell Systems is a global industry leading HT-PEM (High Temperature Polymer Electrolyte Membrane) fuel cell manufacturer. With over 20 years of experience in developing and producing fuel cells, we have solid capabilities in providing innovative fuel cell solutions based on our 5kW HT-PEM fuel cell.

Our solutions are already operational worldwide, powering critical infrastructure as well as mobile and stationary energy systems. With over 1,000 installed systems, we provide reliable, flexible, and sustainable energy, replacing traditional diesel generators and more — without noise or emissions. Our products are scalable, fuel-flexible, and designed to meet the green energy demands of the future. Read more about our product solutions here.

Our product catalogue

With our expertise in methanol fuel cells solutions, we deliver high-performance results for clean energy needs. Our products deliver reliable, efficient, and sustainable power for a wide range of applications.

The Whitecell XGS-55/20 is a carbon-neutral replacement to the traditional diesel generator. It offers the same mobility, flexibility, and autonomy as diesel generators while eliminating noise and pollution.

The XPS is a 5kW modular HT-PEM fuel cell power system and scalable up to 125kW providing the electrical energy you need. The XPS is fuel-flexible which means it can convert methanol, bio-methanol and eMethanol into electrical energy.

The Whitecell XST 2 and 3 stationary system ensures easy integration of up to three XPS-5 units at any site. It is a modular solution and configurable to your requirements.

Key features

Low noise

Sustainable

Low TCO

Safety

The methanol vision

Methanol: A Practical and Scalable Energy Carrier

Methanol is one of the most practical solutions. It can be produced from biomass and other sustainable sources with minimal energy loss. Unlike hydrogen, which requires high-pressure tanks or cryogenic cooling, methanol remains liquid at room temperature and pressure. This makes it significantly easier to handle, store, and transport—similar to gasoline and diesel.

Our Unique Solution

Methanol is already one of the world’s most widely used chemicals, with over 95 billion liters produced annually. It has been safely stored, transported, and handled for over 100 years, and it easily integrates into existing energy systems. Our fuel cells are designed to run on methanol, making them more practical, cost-effective, and easier to implement than fuel cells that run on pure hydrogen.

f.a.q.

You have questions – wE have answers.

Welcome to our FAQ section! Here, you will find answers to the most common questions about fuel cells, their applications, and the advantages. Whether you want to know more about how our fuel cells work, why we use methanol, or how they compare to traditional generators – we have you covered.

Applications and functionality

A fuel cell is a technology that generates electricity through electrochemical reactions, using hydrogen and oxygen to produce both electricity and heat. Unlike traditional internal combustion engines, the fuel cell produces electricity and heat without combustion and the associated emissions. Since a fuel cell has no moving parts, it reduces wear and tear, vibrations, and noise, therefore requiring very little service and maintenance.

Fuel cells are typically used as a replacement for internal combustion engines, such as diesel or gas generators, but without greenhouse gas emissions, noise, and vibrations. Usually, fuel cells are integrated with batteries since the fuel cells recharge the batteries continuously, thus providing the same flexibility, runtime, and mobility as traditional diesel generators. This setup eliminates the charging times and infrastructure required when using batteries alone. Fuel cells are often utilized for backup or continuous power in situations where blackouts are critical and even life-threatening, such as at critical telecom masts and emergency network infrastructure. They are also commonly used as a supplementary part of a carbon-neutral microgrid, integrated with solar, wind, and/or batteries, to ensure continuous power in case of fluctuating wind and sunshine.

Batteries are energy storage devices, whereas fuel cells generate electricity on demand as long as fuel is available. Batteries must be recharged once depleted, while fuel cells can continuously produce electricity if refueled. However, fuel cells and batteries are complementary technologies. A fuel cell acts as a range extender for the battery, enabling continuous or extended runtime. By combining fuel cells and batteries, you get the best of both worlds:

– The flexibility, scalability, and mobility of a traditional diesel generator.

– A vast reduction in carbon footprint, vibration, and noise.

Technology and benefits

Whitecell Systems’ fuel cell module, XPS, is a stand-alone 5kW module with all necessary components integrated, making it an intelligent, scalable, and modular unit that can be used in a variety of applications. The XPS is a HT-PEM (High-Temperature Polymer Electrolyte Membrane) fuel cell, which is similar to the more widely known LT-PEM (Low-Temperature Polymer Electrolyte Membrane) fuel cells. However, it differs in some key areas, primarily its higher operating temperature that provides competitive advantages. HT-PEM fuel cells are highly resistant to carbon monoxide (CO) compared to LT-PEM fuel cells, allowing them to utilize liquid fuels instead of requiring high-purity, pressurized gaseous hydrogen. This capability makes handling, storage, and transportation significantly easier. Moreover, the pre-existing fuel infrastructure can be reused, reducing the cost, complexity, and time needed for implementing the green transition. An additional advantage of HT-PEM fuel cell technology is the waste heat it produces due to its higher operating temperature. This waste heat can be utilized separately, increasing the overall efficiency from 41% to upwards of 90%.

The XGS is a complete plug-and-play power generator, based on Whitecell Systems’ XPS fuel cells, integrated with Li-Ion batteries and an inverter. It combines the best properties of traditional mobile diesel generators while significantly reducing carbon footprint, vibrations, and noise—delivering the best of both worlds. Additionally, the XGS is an intelligent solution, meaning it only uses fuel when there is demand and does not consume fuel in idle mode. Each liter of the methanol fuel mix used in the XGS corresponds to one kWh of electricity. In addition to its built-in 300L fuel tank, the XGS has a connector for external tanks, allowing it to produce power for as long as needed and making refueling simple.

Fuel and sustainability

Methanol is one of the liquid fuels with the highest volumetric energy density and remains liquid at ambient temperatures ranging from -94°C to +65°C. It is one of the most commonly transported chemicals and is globally available with well-established infrastructure. Other renewable fuels, such as hydrogen and ammonia, require new infrastructure to be developed at great cost as these fuels must be pressurized and stored at specific temperatures.

Traditionally, methanol is produced by steam reforming natural gas to create synthesis gas, resulting in so-called “grey” methanol. Compared to diesel, grey methanol reduces the carbon footprint by 40%, particulate emissions by 95%, SOₓ by 99%, and NOₓ by 60% when used in a fuel cell. Methanol can also be produced from renewable sources such as biomass, with bio-methanol achieving a carbon footprint reduction of 60% to 90% depending on the feedstock when compared to diesel, and even more compared to gasoline. When methanol is produced by combining renewable hydrogen with carbon captured from emission sources or directly from the air (Power-to-X technology), the result is eMethanol, which effectively eliminates the carbon footprint, making it a carbon-neutral fuel.

Recycling and maintenance

Whitecell Systems’ fuel cells undergo an overhaul service every 5,000 hours, during which they are retrofitted with new internal components to ensure continuous operation according to product specifications. Additionally, the XPS supports OTA (over-the-air) updates and is continuously maintained to ensure reliable performance. The components replaced during service are either recycled or reused as part of a circular economy. Furthermore, Whitecell Systems offers end-of-life (EOL) handling in a sustainable manner.

Your clean energy journey starts here!

Let us collaborate!